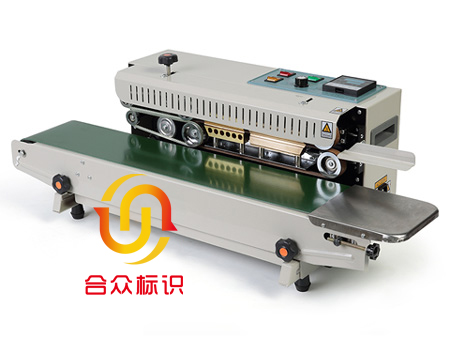

The FRM-980 series ink wheel printing continuous sealing machine is suitable for any sealing of heat sealable materials. The speed is steplessly adjustable, the temperature is controlled, the temperature is adjustable, and the range of adaptation is extremely wide.

First, the product description:

FRM-980 series ink wheel printing continuous sealing machine is suitable for any sealing of heat sealable material. It is printed with solid ink wheel and colored label. It is equipped with dual-purpose printing wheel suitable for R or T-type arrangement. It can be printed with R type. 2 lines of 4 words (PT18), or 3 lines of 5 words (PT10.5), you can also configure the counting device as needed. The FRM-980 series is available in a variety of models: the FRM-980AI is horizontal, the FRM-980AII is vertical, and the FRM-980AIII is floor-standing.

Second, technical characteristics:

1, constant temperature control, temperature adjustable.

2. The speed is steplessly adjustable.

3. The ink wheel is printed clearly, the color is optional, the instant printing is instantaneous, and the adhesion is strong.

Third, technical parameters:

FRM-980AI FRM-980AII FRM-980AIII

Power supply voltage (V / Hz) AC 220/50 110/60

Motor power (W) 50

Electric heating power (W) 300×2

Printing electric heating power (W) 40×2

Sealing line speed (m/min) 0-12 (0-16)

Seal width (mm) 8

Temperature control range (°C) 0-300

Printing category Solid ink wheel

Sealing center to conveyor table distance (mm) 10-40 200-320 10-40

Conveyor table size (L × W) (mm) 930 × 153

The maximum load capacity (kg) of the single piece of the conveyor table ≤1

Conveyor table total load weight (kg) ≤3

Dimensions (L × W × H) (mm) 950 × 400 × 430 950 × 400 × 640 1050 × 560 × 900

Net weight (kg) 45 50 52

Fourth, use, scope of application and characteristics:

(1) This series of products are suitable for poly or poly-single-layer film, poly-hydrocarbon composite film plastic bags which are gathered or gathered into inner layers, and sealed bags of composite flexible packaging bags such as aluminum-plastic paper and plastic.

Due to the characteristics of continuous sealing, it can be made into bags of various sizes and can be used in various packaging lines.

(2) Features:

This series of products has strong sealing and high work efficiency: simple and compact structure, small size: beautiful appearance, advanced technology, low power consumption, convenient operation and maintenance, etc. And has the following characteristics:

1. The use of the cover tape of the occlusion can effectively prevent the sealing pocket from being burnt or polluted, so that the sealing is firm and beautiful.

2. Due to the large capacity of the heater, the heat sealing pressure can be adjusted; and the electronic pre-selected constant temperature control system is adopted, so that various materials and thick packaging bags can be applied for sealing. At the same time, the constant temperature control system allows the heat sealing temperature to be arbitrarily adjusted and automatically insulated, so that the temperature is stable, the heating is uniform, and the sealing quality is stable and reliable.

3. It is equipped with a stepless speed regulation conveying device, which can automatically transfer the packaging bag from the inlet to the outlet to complete the sealing process. And can adapt to various beat requirements automatic line.

4, optional ink wheel printing device, change the font type as needed, can print the date of the seal at the same time, the storage period, the shelf life, etc., the sealing pattern and the slogan are clear and beautiful.

5. The width of the bag is not limited to any length, and the bag can be heat-sealed smoothly regardless of the size of the bag.

V. Use and operation:

(1) Boot operation:

1. According to the width of the packaging bag, adjust the position of the printing. Generally, the printing position has been adjusted before leaving the factory.

2. Press the power switch, and the indicator light in the switch is on.

3. Press the conveyor switch, the indicator light in the switch is on, turn the speed control button to adjust the required speed.

4. Press the heating switch, the indicator light in the switch is on, and rotate the knob of the sealing temperature adjustment machine and the printing thermostat respectively, so that the indicator on the knob points to the desired temperature value, and when the temperature reaches the set value, it can start. Sealing and printing operations.

5. Press the cooling switch as needed (single layer film needs to be cooled), the indicator light in the switch is on, and the cooling fan is activated.

(2) Boot operation:

In order to extend the life of the sealing tape, ink wheel and printing wheel, the heater switch must be disconnected before stopping, so that the conveying part can still run for 15-20 minutes, then it can be shut down.

(3) Seal quality adjustment:

According to the material thickness of the sealing material and the size of the packaging bag, the speed and temperature should be adjusted to achieve satisfactory sealing quality and high production efficiency.

1. There are related relationships between sealing material, sealing temperature and sealing speed. In the same material, the speed can be increased when the temperature is selected high, and the temperature should be lower when the speed is low. The thicker the film thickness, the higher the temperature and the lower the speed, and vice versa.

2. Before the actual operation, it is necessary to make a preliminary test, adjust the temperature and the corresponding sealing temperature, and repeat it several times to find the temperature and speed that are satisfactory for the sealing quality and efficiency, and then carry out the formal operation.

3. When sealing a single layer of plastic film in ordinary poly, it is necessary to sweep the fan for cooling. In the initial test, the temperature should be gradually increased to prevent the temperature from being too high and the film to be melted on the sealing tape. If the bonding occurs, the peeling should be removed in time to ensure the sealing quality and protect the sealing tape.

4. When the composite film material is sealed, the selected temperature range is much higher than that of the single-layer film, and generally no fan cooling is required.

5. The pressure of the embossing wheel is closely related to the quality of the sealing. It is advisable to adjust the pressure to a clear pattern. The pressure is too high, affecting the life of the parts, the pressure is low, the pattern is not clear, and the sealing strength is lowered.

Henan Union Coding Tech Co., Ltd. is a manufacturing company specializing in the research, development, production, sales and service of automated packaging machinery products. In the "market-oriented, credibility to win" business purposes, mainly engaged in automatic labeling machine, thermal transfer coding machine,ribbon coding machine, ink wheel coding machine and other products have been in pharmaceutical, daily, food , pesticides, seeds, lubricants and other industries are widely used; coding consumables: Coding Ribbon,Hot ink roller,TTO ribbon, labels and other consumables products sell well all over China.